PROCESSING

S.C.M.

performs various types of processing:

- LASER Cutting

- Bending

- Rolling

- Welding

- Tube and profile bending

- Barrel finishing

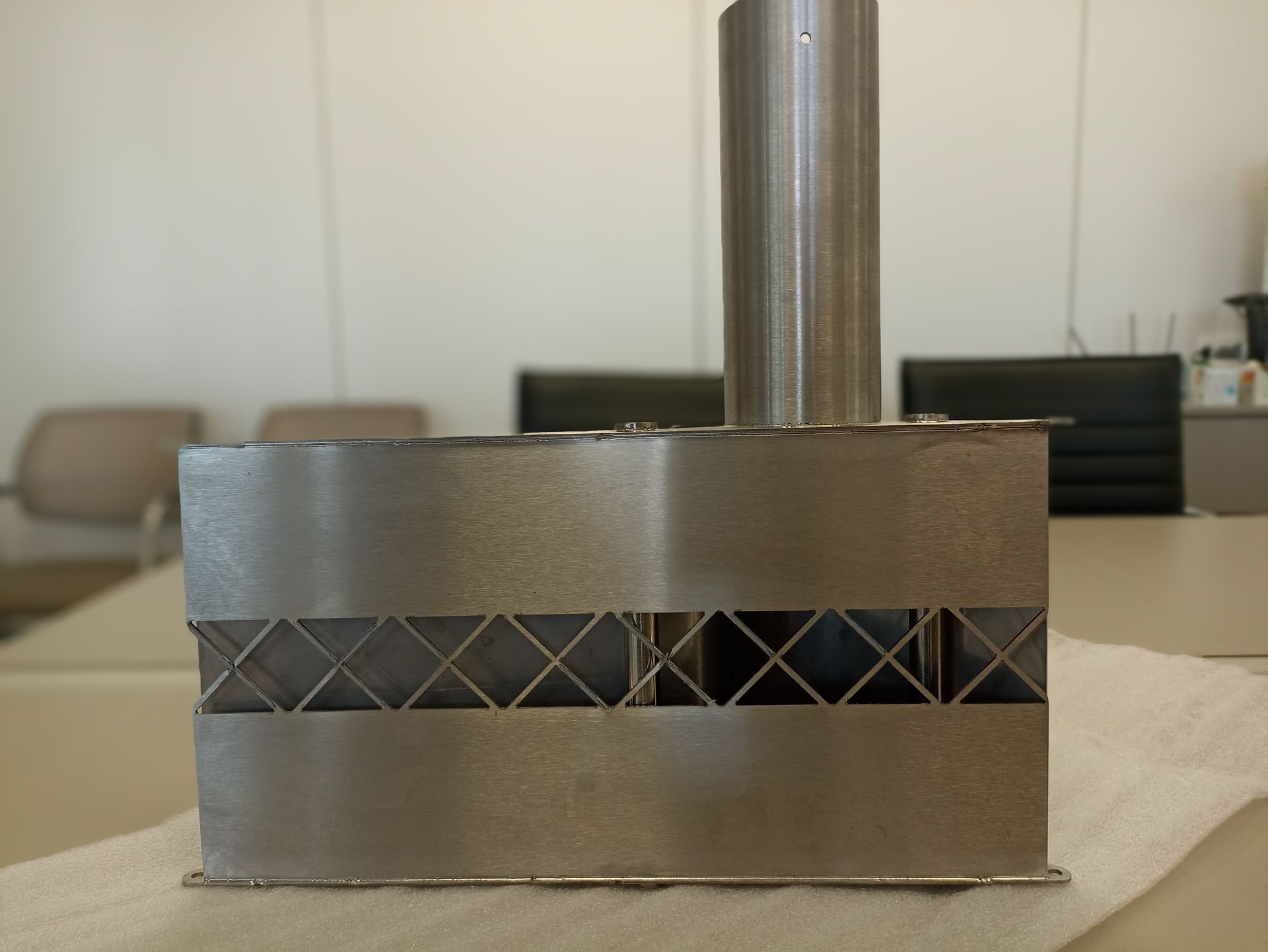

- Assembly

LASER CUTTING

The ENSIS 3015 AJ - Rotary Index system revolutionises the concept of fibre cutting on thin materials and significantly expands the range of workable thicknesses.

Other innovative features of the system include a power of 3000 W, automatic beam adjustment based on the sheet thickness, and an extremely compact structure.

With the built-in Rotary Index system, important features are added for fast and stable tube cutting, ensuring a defect-free end product and a considerable increase in production.

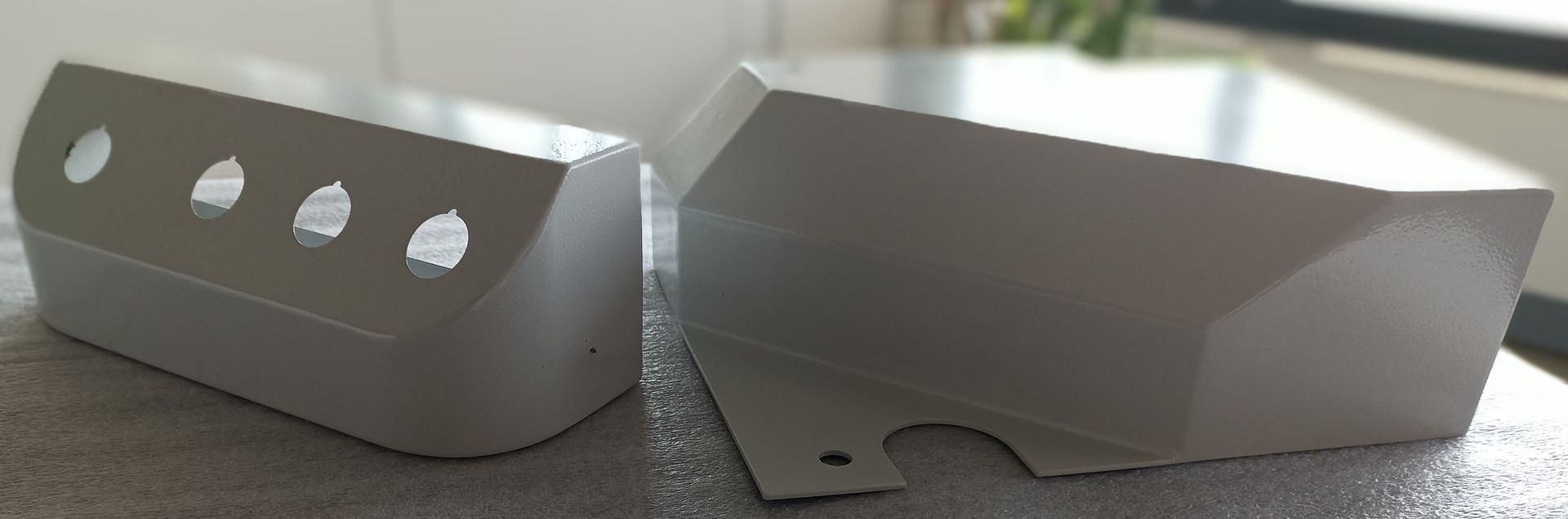

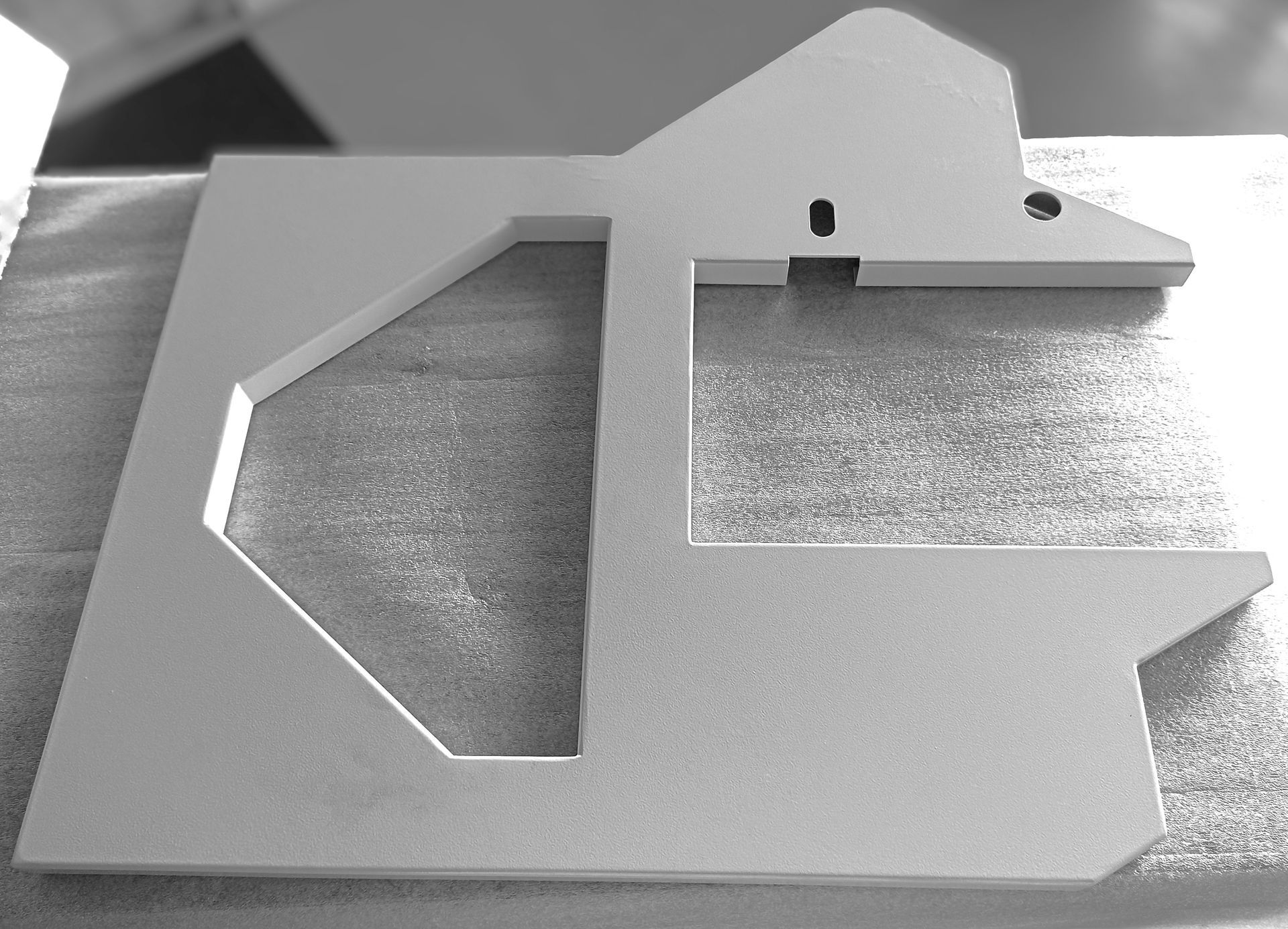

BENDING

S.C.M. has 2 bending machines:

Amada HG Series Press Brake:

It is a high-level, versatile, high-speed bending machine with maximum bending precision. It ensures significant energy savings and a user interface that makes it easy to use, with increasingly advanced features that help reduce delivery times and ensure high-quality bending results. The press brake is equipped with AFH and One Stroke tools, which are the optimal solution to minimise setup operations.

Amada HD 1003 ATC Press Brake:

It is a press brake with Automatic Tool Changer (ATC). Machine setup is one of the most critical operations that often require time, precision, and effort on the part of the operator. With the ATC system, machine setup is performed automatically, reducing setup times, eliminating strenuous activities for the operator, and reducing the risk of errors. This press brake is the ideal solution for small and heterogeneous batches that require frequent tool changes.